Engineers have always loved using ceramic parts. They are durable, easy to use and the easiest to handle them. Ideal for crafting parts of aircraft or rockets. Thus, for example, heat shield tiles on the shuttle are always made of ceramic.

This discovery could open a new door to an entirely new class of ceramic aircraft engines. Perhaps even to a hypersonic aircraft that can fly from New York to Tokyo in a few hours.

"If you are moving very fast, about 10 times faster than the speed of sound in the atmosphere, any vehicle will heat up tremendously due to air friction," said Tobias Schadler, a senior researcher at HRL Laboratories in Malibu, California. "People want to build air-resistant vehicles, and for this they need a new kind of ceramics to create the entire vehicle envelope."

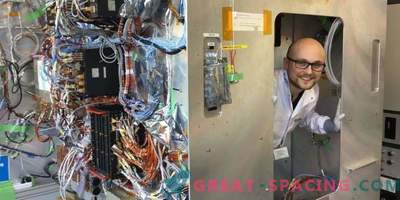

Schadler and his colleagues from HRL invented an innovative resin formula that can be used in 3D printing of objects of almost any shape and size. The printed resin can be used as the basis of the component with high strength. The resulting material can withstand ultra-high temperatures above 1700 degrees Celsius (3092 Fahrenheit), which is 10 times higher than the possibility of similar materials.

In this respect, it is much more difficult to work with ceramics than with plastic or metal, because it cannot be processed so easily. This fact noted Schadler, who is the author of this new study.

But the team of the scientist was able to figure out how to deceive the ceramics and make them work for themselves.

"We have a pre-made ceramic resin that can be printed as a polymer. There is some material shrinkage, but very uniform, so you can predict it."

The overall picture is as follows: this method can help designers and designers of rockets and satellites who additionally create a lot of special small parts that can withstand heat. It occurs while driving at high speed.

Ceramic alumina is used in a new ion engine. Its electricity is used to heat the gas and generate ions. "Ceramics is really good if your goal is to reduce machine frame wear," said Schadler.

The Pentagon branch funds various projects to discover new ways to create lighter, stronger and more heat-resistant materials for aerospace and military applications.

"The method described on these papers brings us closer to achieving the required material properties that are not usually found together. For example, strength and low density or small mass and huge detail size," said Stephanie Tompkins, director of defense science in advanced defense research .

If you figure out how to make customized 3D printed parts from ceramics, then this will be a giant scientific breakthrough that will help create new gas power plants, gas engines, and more.